Engineering excellence across a wide range of vehicles

In June 1991, Paneltex was established in a small factory in Hull, led by founder Chris Berridge. This was a strategic move following the Food Safety Act of 1990, which enshrined the concept of the cold chain in the UK. The Paneltex mission was to produce insulated panels and portable cold stores designed to ensure goods were kept at the correct temperatures from point of manufacture to point of sale.

Today, Paneltex products are known for their thermal efficiency, durability, ease of operation, and safety features, all of which ensure their market-leading position.

Bespoke designs and consistency at high volume

Paneltex offers a wide range of refrigerated vehicle solutions:

Tailored solutions for every need

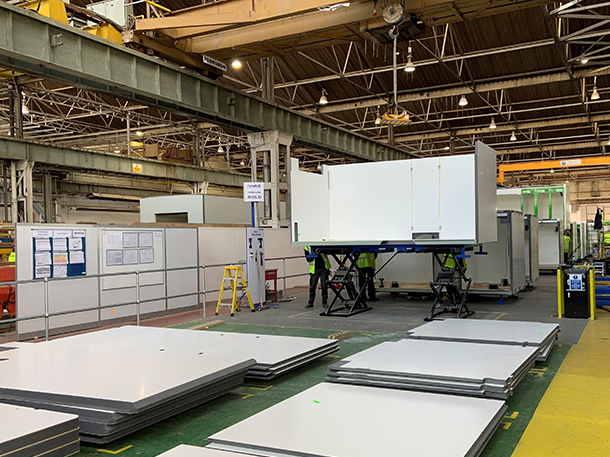

The unique strength of Paneltex lies in our in-house manufacturing processes, covering everything from chassis and panels to assembly, fit-out, and final paint. This comprehensive approach positions us uniquely to provide a truly tailored and customised range of quality-controlled refrigerated vehicles. From the largest double-deck trailer on the road in the UK to the smallest delivery van, we have designed and built an extensive array of temperature-controlled vehicles for numerous renowned fleets.

Design engineering supporting volume production

Paneltex’s in-house Design, Electrical, and Manufacturing Engineering teams allow us to develop highly customised products which solve our customers’ real-world challenges. These products can then be taken to full-scale manufacturing, within Paneltex standard production processes. R&D focuses can include:

A commitment to sustainable cold-chain transport

Paneltex actively pursues innovation, material efficiency and production optimisation to reduce environmental impact and enhance operational sustainability. Continuous improvement is embedded in the manufacturing process and aligned with future-oriented cold-chain logistics solutions.

A focus on sustainability in products and processes

Paneltex has a robust commitment to sustainability, efficiency, and environmental protection throughout its product lifecycle, manufacturing processes, and supply chain.

Through strategic resource optimisation and rigorous recycling and waste reduction initiatives, we have made noteworthy strides in safeguarding our natural environment.

Whilst proud of our accomplishments so far, we recognise the ongoing imperative to advance further. We treat our commitment to sustainability as a fundamental principle propelling us towards a carbon neutral future, as we strive to safeguard the environment for future generations.

See the website